Mini-nuclear companies are looking for buyers who think small

A newly approved reactor could carve out a new future for nuclear energy. Here’s how it works

Abe Musselman • December 29, 2020

A new generation of reactors shrink nuclear plants to a fraction of the size. [Credit: NRCgov | Creative Commons BY-NC-ND 2.0]

For some people, the phrase “nuclear power plant” calls to mind the enormous gray cooling towers you might find along interstate highways or in the opening credits of The Simpsons. But smaller, more compact reactors have been in use for decades, including aboard ships and submarines.

The latest generation of small modular reactors, or SMRs, are designed to be put together in a factory and shipped out to build a power plant, unit by unit. Nuclear advocates hope SMRs will be a turning point for nuclear power, which faces an uncertain future due to high costs and safety concerns. SMRs, they say, are safer than conventional nuclear plants and cheaper to build.

The Oregon-based company NuScale has become the face of SMRs in the U.S. This August, their design became the first to receive a final safety evaluation report from the Nuclear Regulatory Commission, which affirms that the design meets the commission’s safety standards. This means energy providers can include the design in their applications to build new nuclear plants.

In the next phase, the commission will need to amend its regulations to include the new design before it can issue a final certification. This stage of the process will be open to comment from the public early next year, so it’s a good time to talk about what NuScale wants to build. Here are some basics:

Design

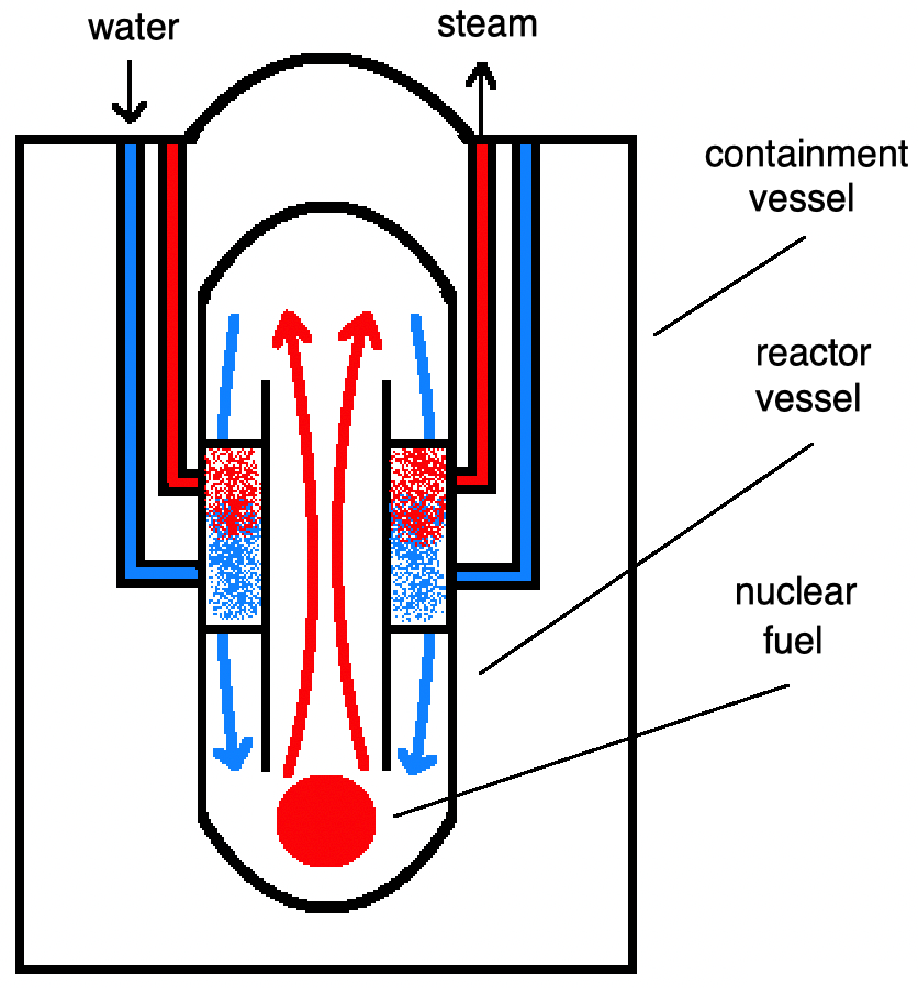

NuScale’s reactor measures a total of 76 feet by 15 feet. Its basic design consists of two nested compartments: the reactor vessel, which contains the uranium fuel, and a larger containment vessel for safety.

In NuScale’s design, water circulates inside the reactor vessel (see arrows) and heats a second supply of water in the surrounding pipes. [Credit: Abe Musselman]

All nuclear reactors use rods of uranium fuel to heat water, producing steam which turns a turbine and generates electricity. The uranium atoms in the fuel are radioactive, and they break down spontaneously. When they do, they shoot out neutrons, which crash into other uranium atoms, causing them to split, and so on, releasing heat in the process. This reaction is called nuclear fission.

Unlike conventional reactors, NuScale’s design doesn’t use pumps to circulate the water in the core. “Everything is driven by the laws of physics and natural buoyancy,” says Renae Lenhof, a nuclear fuels engineer at NuScale. Getting rid of pumps and other internal parts is one way NuScale has been able to shrink the size of their reactor.

Inside the reactor core, water flows over the fuel rods, picks up heat, and carries it to the top of the reactor vessel, where it heats a separate supply of water to generate steam. As it cools, the water then falls back to the bottom of the reactor vessel to start the process over. A reactor in which the reactor core and steam generator are kept separate is known as a pressurized water reactor.

Similar SMRs have been designed by the American companies Holtec and Westinghouse. Westinghouse’s AP-1000, an existing large reactor, uses some of the same design principles as NuScale’s, and two AP-1000 reactors are set to come online next year at the Vogtle Electric Generating Plant in Georgia. A design by the China National Nuclear Corporation is the SMR closest to market, according to the World Nuclear Association. But no design besides NuScale’s has yet passed safety review in the U.S.

Safety

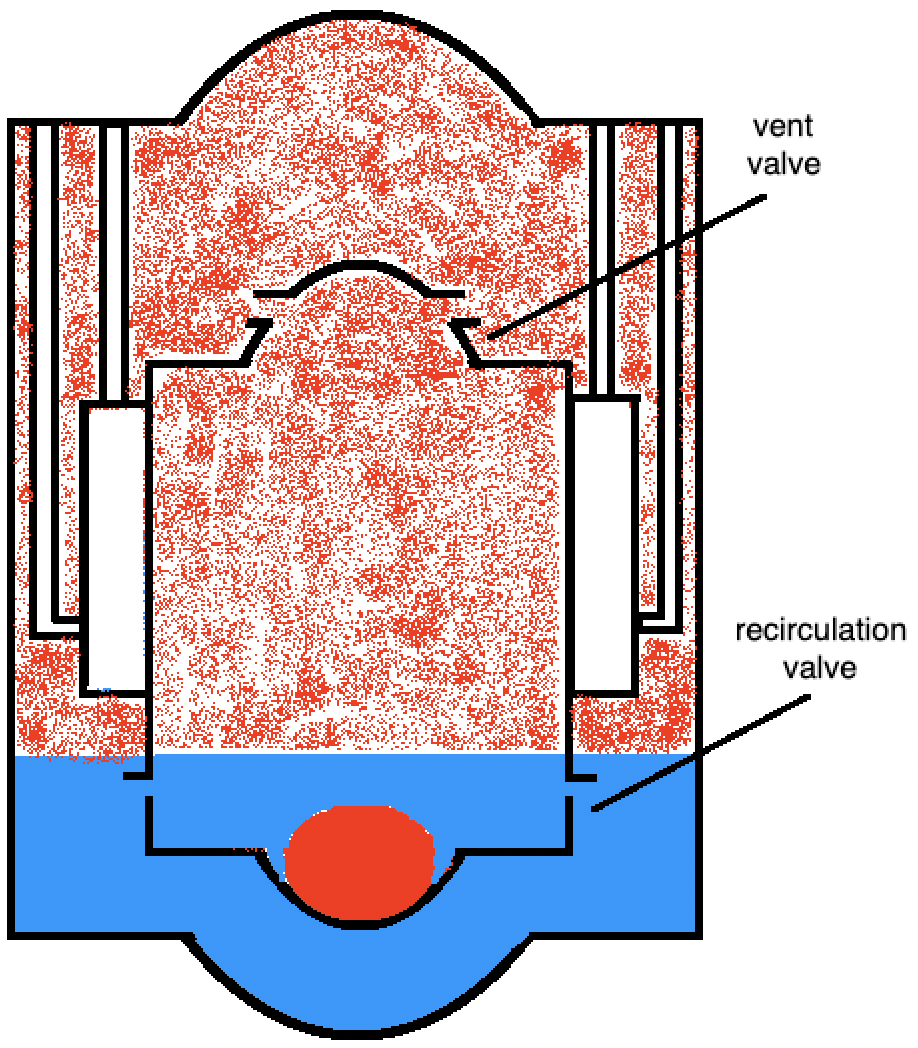

In a NuScale power plant, up to twelve reactors would sit side by side, immersed in a pool of water lined with concrete and steel. If a reactor overheats, two vents in the top of the reactor shell would open, allowing steam to escape into the containment vessel. The steam would then condense and drip down to cool the reactor while also releasing heat into the pool outside the reactor.

NuScale’s passive shutdown feature: the vent valves open and steam escapes into the containment vessel. The steam condenses into water and re-enters the reactor vessel through the recirculation valves. [Credit: Abe Musselman]

These are known as passive safety features, designed to work automatically with little or no human oversight. These features, NuScale says, eliminate the need for some personnel and active safety features like emergency pumps, which need an additional source of power.

But not everyone is convinced the design is foolproof. During the Nuclear Regulatory Commission’s review process, reviewers found that the steam released from the reactor core leaves behind the element boron, which is added to the water to keep the fission reaction under control. When the boron-free water reenters the reactor vessel, they said, it could restart the reaction.

Earlier this year, NuScale made adjustments to the design and certain settings in the reactor to keep the level of boron in the recirculating water high enough to control the reaction until it’s no longer at risk of restarting. “The boron redistribution issue would occur later, after the reactor had been safely shut down,” says Scott Burnell, a public affairs officer at the commission. He says the commission has taken NuScale’s changes into account and concluded that the design meets its safety requirements. NuScale declined to provide more specific comment.

In their most recent letter to the commission, the reviewers who first raised concerns about boron dilution said they weren’t fully satisfied and would continue to look into the issue.

Nuclear critics say NuScale should be doing more to improve its design, especially now that it has passed the safety review process. Edwin Lyman, director of nuclear power safety at the nonprofit Union of Concerned Scientists, says the commission is under pressure from lawmakers and the industry to relax its requirements in order to bring SMRs to market more quickly.

NuScale, however, has denied requesting looser safety regulations, and Burnell, the commission spokesperson, emphasizes that the commission sets its own schedule for reviewing and approving reactor designs.

Cost

A Westinghouse-built plant in Tennessee, which began operating in 2016, is the only nuclear plant to be built in the U.S. in the last 20 years. One of the main barriers to setting up a new nuclear plant is the initial investment. While the precise cost of building one today is difficult to predict, a 2008 report by the consulting group Synapse Energy found that a new 1,110-megawatt plant could cost $6 billion to $9 billion.

To make up for these initial outlays, conventional nuclear plants often rely on economies of scale. By building more or larger reactors, companies can cut down on construction and operation costs.

SMR designers are trying a different strategy. To reduce costs, NuScale aims to make its reactor as simple and inexpensive to manufacture as possible. By streamlining the production process, it hopes to produce many reactors at a lower cost and sell customers exactly as much generating capacity as needed.

NuScale estimates its 720-megawatt power plant will cost $2.5 billion, and envisions its product as a tailor-made solution for small energy grids. “We’re trying to get in the market of local communities who want reliable baseload power that might be currently generated with less carbon-efficient sources,” says NuScale engineer Lenhof.

The company has signed exploratory agreements with a handful of governments and utility companies around the world. But it has announced plans to build only one power plant so far, part of a partnership with Utah Associated Municipal Power Systems, a network of local energy providers with member towns and cities throughout the Western U.S.

The region is growing, and it’s looking to increase its renewable energy supply, says LaVarr Webb, a spokesperson for the organization. The group hopes to begin building the first NuScale power plant at the Idaho National Laboratory in 2025, following approval from the Nuclear Regulatory Commission.

Other buyers will have to wait until 2027, according to Diane Hughes, vice president of marketing for NuScale. The company has further tests scheduled through 2021 and is focused on staying on track for commercial factory production, she says.

Customers like Utah Associated Municipal Power Systems, which doesn’t need enough electricity to justify a large nuclear plant, are exactly what NuScale has in mind. “Without this new-generation nuclear, I’m sure UAMPS wouldn’t be considering [nuclear power],” says Webb.

1 Comment

Thanks for the info!! Did the state/governor of Tennessee recently strike a deal with NuScale??

There was a recent blurb but no real details. Can youPLEASE check this out??